3838 (S58E) E-Series, NP0, Low ESR Capacitor Multi-Layer High-Q Capacitors

Johanson Silver E-Series Capacitors are High RF power and low loss ceramic multilayer RF capacitors (High Frequency MLCC’s). This ultra-High-Q E-Series of products use nearly pure silver electrodes, which is a superior high frequency conductor compared to palladium. Accordingly, the performance of these products sets a new standard in the industry for low ESR capacitors.

Utilizing a modern dielectric system, these NPO capacitors exhibit the lowest losses, excellent high voltage performance and excellent temperature stability.

Available in numerous termination and Lead styles, as well as custom Lead configurations.

Key Features:

- Standard EIA Size: 3838

- Capacitance Range 1.0 - 5100 pF

- RF Power Application

- Lowest ESR in Class

- Excellent high-Q performance

- HF to Microwave frequencies

- High Self-Resonance Frequencies

- Exhibits NP0 temperature characteristics

- RoHS Compliant

- Temperature range is -55° C to +125° C*.

Circuit Applications

- MRI Coils

- Commmunication amplifiers

- Power converters

- Filter Networks

- Circuit Matching

- Amplitude modulators

- Antenna Matching, high power circuitry

- RF plasma generators (SC's)

- Laser generators

- Matching boxes (Military & Industrial)

- Security systems

- Lighting protection

3838 (S58E) E-Series Capacitors Information

Capacitance Range

| Case Size: | 3838 |

| Capacitance: | 1.0 - 5100 pF |

| Operating Temperature: | -55 to +125°C |

| Insulation Resistance: | >1000 ΩF or >10 GΩ, whichever is less @ 25°C WVDC |

| Temperature Coefficent: | ± 30ppm /°C, -55 to 125°C |

| Dissipation Factor (TYP.): | < 0.05% @ 1 MHz |

Model Selection

| EIA Size/Cap. Value | RF Power Applications | |||

|---|---|---|---|---|

| 3838 (S58E) | ||||

| pF | Code | Voltage | ||

| 0.6 | 0R6 | A B C D |

3600V | 7200V |

| 0.7 | 0R7 | 3600V | 7200V | |

| 0.8 | 0R8 | 3600V | 7200V | |

| 0.9 | 0R9 | 3600V | 7200V | |

| 1.0 | 1R0 | 3600V | 7200V | |

| 1.1 | 1R1 | 3600V | 7200V | |

| 1.2 | 1R2 | 3600V | 7200V | |

| 1.3 | 1R3 | 3600V | 7200V | |

| 1.4 | 1R4 | 3600V | 7200V | |

| 1.5 | 1R5 | 3600V | 7200V | |

| 1.6 | 1R6 | 3600V | 7200V | |

| 1.7 | 1R7 | 3600V | 7200V | |

| 1.8 | 1R8 | 3600V | 7200V | |

| 1.9 | 1R9 | 3600V | 7200V | |

| 2.0 | 2R0 | 3600V | 7200V | |

| 2.1 | 2R1 | 3600V | 7200V | |

| 2.2 | 2R2 | 3600V | 7200V | |

| 2.4 | 2R4 | 3600V | 7200V | |

| 2.7 | 2R7 | 3600V | 7200V | |

| 3.0 | 3R0 | 3600V | 7200V | |

| 3.3 | 3R3 | 3600V | 7200V | |

| 3.6 | 3R6 | 3600V | 7200V | |

| 3.9 | 3R9 | 3600V | 7200V | |

| 4.3 | 4R3 | 3600V | 7200V | |

| 4.7 | 4R7 | 3600V | 7200V | |

| 5.1 | 5R1 | B C D |

3600V | 7200V |

| 5.6 | 5R6 | 3600V | 7200V | |

| 6.2 | 6R2 | 3600V | 7200V | |

| 6.8 | 6R8 | 3600V | 7200V | |

| 7.5 | 7R5 | 3600V | 7200V | |

| 8.2 | 8R2 | 3600V | 7200V | |

| 9.1 | 9R1 | 3600V | 7200V | |

| 10 | 100 | F G J K |

3600V | 7200V |

| 11 | 110 | 3600V | 7200V | |

| 12 | 120 | 3600V | 7200V | |

| 13 | 130 | 3600V | 7200V | |

| 15 | 150 | 3600V | 7200V | |

| 16 | 160 | 3600V | 7200V | |

| 18 | 180 | 3600V | 7200V | |

| 20 | 200 | 3600V | 7200V | |

| 22 | 220 | 3600V | 7200V | |

| 24 | 240 | 3600V | 7200V | |

| 27 | 270 | 3600V | 7200V | |

| 30 | 300 | 3600V | 7200V | |

| 33 | 330 | 3600V | 7200V | |

| 36 | 360 | F G J K |

3600V | 7200V |

| 39 | 390 | 3600V | 7200V | |

| 43 | 430 | 3600V | 7200V | |

| 47 | 470 | 3600V | 7200V | |

| 51 | 510 | 3600V | 7200V | |

| 56 | 560 | 3600V | 7200V | |

| 62 | 620 | 3600V | 7200V | |

| 68 | 680 | 3600V | 7200V | |

| 75 | 750 | 3600V | 7200V | |

| 82 | 820 | 3600V | 7200V | |

| 91 | 910 | 3600V | 7200V | |

| 100 | 101 | 3600V | 7200V | |

| 110 | 111 | 3600V | 7200V | |

| 120 | 121 | 3600V | 7200V | |

| 130 | 131 | 3600V | 7200V | |

| 150 | 151 | 3600V | 7200V | |

| 160 | 161 | 3600V | 7200V | |

| 180 | 181 | 3600V | 7200V | |

| 200 | 201 | 3600V | ||

| 220 | 221 | 3600V | ||

| 240 | 241 | 3600V | ||

| 270 | 271 | 3600V | ||

| 300 | 301 | 3600V | ||

| 330 | 331 | 3600V | ||

| 360 | 361 | 3600V | ||

| 390 | 391 | 3600V | ||

| 430 | 431 | F G J K |

2500V | |

| 470 | 471 | 2500V | ||

| 510 | 511 | 2500V | ||

| 560 | 561 | 2500V | ||

| 620 | 621 | 2500V | ||

| 680 | 681 | 2500V | ||

| 750 | 751 | 2500V | ||

| 820 | 821 | 2500V | ||

| 910 | 911 | 1000V | ||

| 1000 | 102 | 1000V | ||

| 1200 | 122 | 1000V | ||

| 1500 | 152 | 1000V | ||

| 1800 | 182 | 1000V | ||

| 2200 | 222 | 1000V | ||

| 2700 | 272 | 500V | ||

| 3300 | 332 | 500V | ||

| 3900 | 392 | 500V | ||

| 4700 | 472 | 500V | ||

| 5100 | 512 | 500V | ||

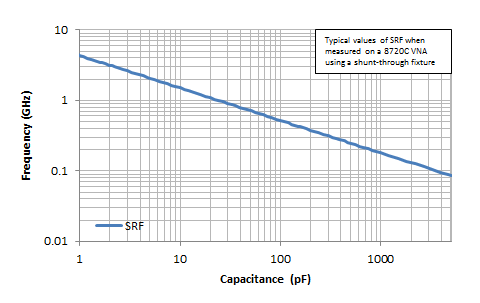

Resonant frequencies

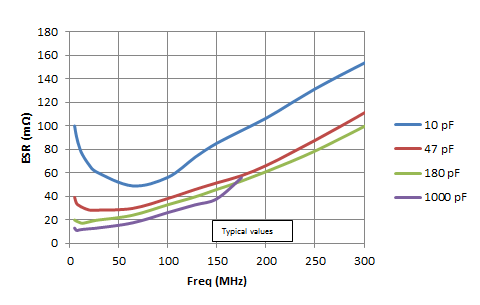

ESR curves

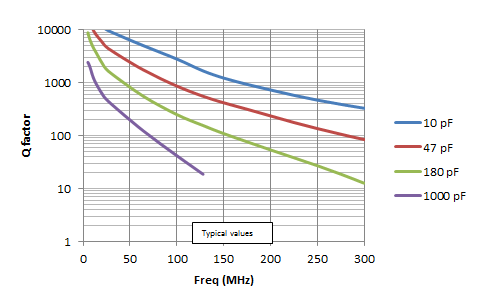

Q factor curves

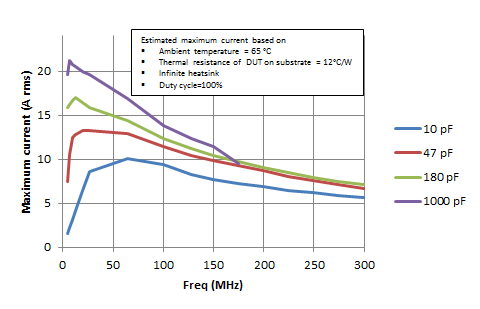

Maximum RF Current (estimated)

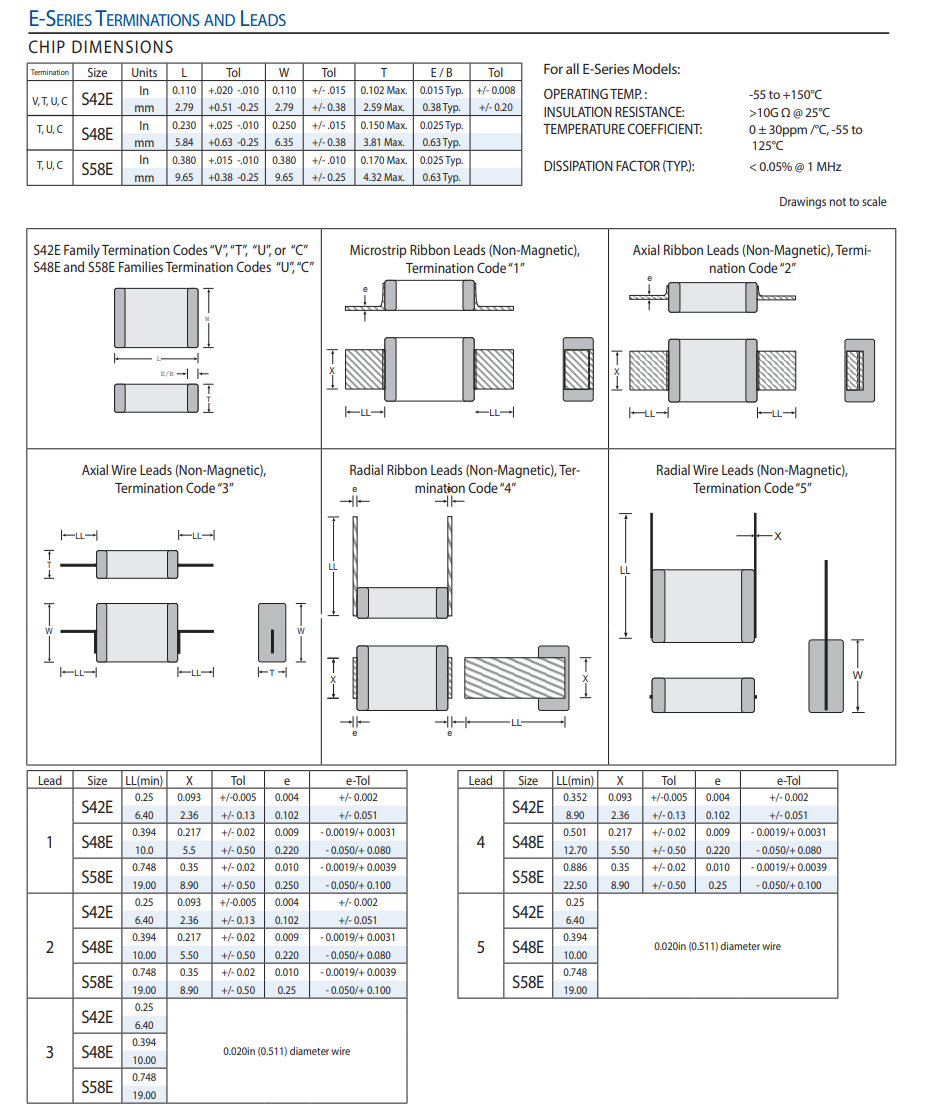

Mechanical Characteristics

Environmental Specifications

| Specification | Test Parameters | |

| Life test: | No mechanical damage. Capacitance change: ±3.0% or 0.3 pF Q>500 I.R. >1 G Ohms Breakdown voltage: 2.5 x WVDC | Applied voltage: 200% rated voltage, 50 mA max. Temperature: 125°±3°C Test time: 1000+48-0 hours |

| Thermal Cycle: | No mechanical damage. Capacitance change: ±2.5% or 0.25pF Q>2000 I.R. >10 G Ohms | 5 cycles of: 30±3 minutes @ -55°+0/-3°C, 2-3 min. @ 25°C, 30±3 min. @ +125°+3/-0°C, 2-3 min. @ 25°C Measure after 24±2 hour cooling period |

| Humidity, Steady State: | No mechanical damage. Capacitance change: ±5.0% or 0.50pF max. Q>300 I.R. = 1 G-Ohmbr /> Breakdown voltage: 2.5 x WVDC | Relative humidity: 90-95% Temperature: 40°±2°C Test time: 500 +12/-0 Hours Measure after 24±2 hour cooling period |

| Humidity, Low Voltage: | No mechanical damage. Capacitance change: ±5.0% or 0.50pF max. Q>300 I.R. = 1 G-Ohm min. Breakdown voltage: 2.5 x WVDC | Applied voltage: 1.5 VDC, 50 mA max. Relative humidity: 85±2% Temperature: 40°±2°C Test time: 240 +12/-0 Hours Measure after 24±2 hour cooling period |

| Vibration: | No mechanical damage. Capacitance change: ±2.5% or 0.25pF Q>1000 I.R. = 10 G-Ohm Breakdown voltage: 2.5 x WVDC | Cycle performed for 2 hours in each of three perpendicular directions. Frequency range 10Hz to 55 Hz to 10 Hz traversed in 1 minute. Harmonic motion amplitude: 1.5mm. |

How to Order

Valid options are shown except for Capacitance

A typical PN is QEFM362Q0R6A3A2001W. This part number breaks down as follows:

Capacitors High-Q MLC E-Series, 2525, Hi-Q NP0/C0G, 2500V, 0.5pF±0.05pF, Axial Ribbon Lead, Waffle Pack

New Johanson Global Part Number Breakdown

* Not all combinations create valid part numbers, ask our Apps Engineering Team for assistance creating a valid part number Request for assistanceClick below to see the new Global Part Number Reference Chart for this product

Legacy How to Order Information