Single Layer, Microwave Capacitors (SLC)

Features:

- Offered in a wide range of dielectrics for very high frequency applications.

- Available in sizes from 0.25 x 0.25mm (10 x 10mil) to 5 x 5mm (90 x 90mil).

- Used in military infrastructure and industrial markets.

- Known for excellent performance, reliability, and consistency in volume production

Common Applications:

- Microwave Integrated Components

- GaAs Integrated Circuits

- RF/Microwave Components

- DC Block, Bypass, Tuning

| Metalization Type | TiW/Au (Titanium-Tungsten/Gold) | TiW/Ni/Au (Titanium-Tungsten/Nickel/Gold) | TiW/Pt/Au (Titanium-Tungsten/Platinum/Gold) |

|---|---|---|---|

| Termination Code | S2 | S1 | S0 |

| Attachment Compatibility Wire / Ribbon Bonding | Wire / Ribbon Bonding Silver or Gold Conductive Epoxy Au/Ge or Au/Si Eutectic Preform Excellent High Temperature Resistance (400°C) Unsuitable for Pb/Sn or Au/Sn Soldering | Pb/Sn or Au/Sn Soldering Au/Sn Eutectic Preform Moderate High Temp. Resistance (325°C) Long term high temperature may cause Ni diffusion and wire bond problems on Au/Ge | Pb/Sn or Au/Sn Soldering Au/Sn Eutectic Preform Moderate High Temp. Resistance (325°C) Long term high temperature may cause Ni diffusion and wire bond problems on Au/Ge |

| Dielectric Code | Constant (K) | Temperature Coefficient | Temperature Range | Dissipation Factor (DF) | Test Conditions | Tolerances |

|---|---|---|---|---|---|---|

| G | 23 - 76 | 0 ± 30ppm | -55°C to +125°C | ≤ 0.15% @ 1MHz | 1 | B,C,D (A, <2pF) (F-K, >10pF) |

| D | 160 | -1,500 +500ppm / -946ppm | -55°C to +125°C | ≤ 0.25% @ 1MHz | 1 | J, K, M (B, C, D <10pF) |

| E | 440 | 2,200 +500ppm / -1,086ppm | -55°C to +125°C | ≤ 0.25% @ 1MHz | 1 | J, K, M (C, D <10pF) |

| P | 725 - 1,410 | ± 10% | -55°C to +125°C | ≤ 2.50% @ 1kHz | 2 | J, K, M |

| W | 2,300 - 4,100 | ± 15% | -55°C to +125°C | ≤ 2.50% @ 1kHz | 2 | J, K, M |

| U | 8,500 | +22% - 56% | +10°C to +85°C | ≤ 4.00% @ 1kHz | 2 | M, X |

| Y | 15,000 | +22% - 82% | -30°C to +85°C | ≤ 4.00% @ 1kHz | 2 | M, X |

| A | 15,000 - 65,000 | ± 15% | -55°C to +125°C | ≤ 2.50% @ 1kHz | 2 | K, M, X |

| Voltage Rating | 16; 25; 50; & 100 WVDC |

| Dielectric Strength | 2.5 x WVDC min, 25°C, 50 mA max |

| Test Conditions | Class 1 1.0 ± 0.2 VRMS @ 1MHz, 25°C Class 2 For values ≤ 100pF: 1.0±0.2 VRMS @ 1MHz, 25°C; for ALL other Values: 1.0±0.2 VRMS @1KHz,25°C Class 3 1.0±0.2 VRMS @ 1KHz |

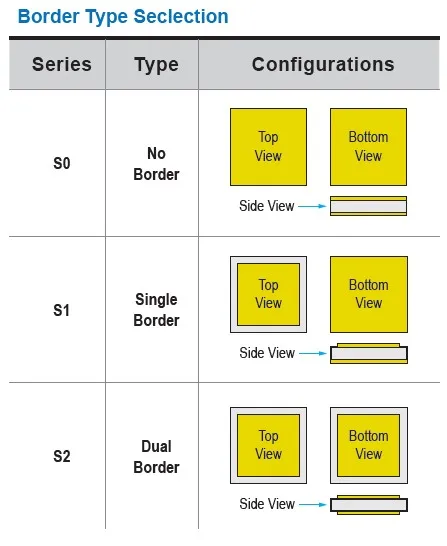

(W) = Width. (L) = Length. (T) = Thickness. (B) = Border.

| S0AA | S0AG | S0AL | S0AP | S0AU | S0BC | S0BG | S0BL | S0BQ | S0BR | S0BT | ||

| (W) | inch | 0.010" +0.001"/-0.003" | 0.012" +0.001"/-0.003" | 0.015" +0.001"/-0.003" | 0.020" +0.001"/-0.003" | 0.025" +0.001"/-0.003" | 0.030" +0.001"/-0.003" | 0.035" ±0.005" | 0.040" ±0.005" | 0.050" ±0.010" | 0.070" ±0.010" | 0.090" ±0.010" |

| (mm) | (0.254mm +0.025mm/-0.076mm) | (0.305mm +0.025mm/-0.076mm) | (0.381mm +0.025mm/-0.076mm) | (0.508mm +0.025mm/-0.076mm) | (0.635mm +0.025mm/-0.076mm) | (0.762mm +0.025mm/-0.076mm) | (0.889mm ±0.127mm) | (1.016mm ±0.127mm) | (1.270mm ±0.254mm) | (1.778mm ±0.254mm) | (2.286mm ±0.254mm) | |

| (L) | inch | 0.012" Max | 0.015" Max | 0.020" Max | 0.025" Max | 0.030" Max | 0.035" Max | 0.040" Max | 0.045" Max | 0.060" Max | 0.080" Max | 0.100" Max |

| (mm) | (0.305mm Max) | (0.381mm Max) | (0.508mm Max) | (0.635mm Max) | (0.762mm Max) | (0.889mm Max) | (1.016mm Max) | (1.143mm max) | (1.524mm Max) | (2.032mm Max) | (2.450mm Max) | |

| (T) | inch | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" |

| (mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | |

| (T) for A - Dielectric | inch | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 |

| (mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | |

| S1AA/S2AA | S1AG/S2AG | S1AL/S2AL | S1AP/S2AP | S1AU/S2AU | S1BC/S2BC | S1BG/S2BG | S1BL/S2BL | S1BQ/S2BQ | S1BR/S2BR | S1BT/S2BT | ||

| (WxL) | inch | 0.010" ±0.001" | 0.012" ±0.001" | 0.015" ±0.001" | 0.020" ±0.001" | 0.025" ±0.001" | 0.030" ±0.001" | 0.035" ±0.001" | 0.040" ±0.001" | 0.050" ±0.05" | 0.070" ±0.05" | 0.090" ±0.05" |

| (mm) | (0.254mm ±0.025mm) | (0.305mm ±0.025mm) | (0.381mm ±0.025mm) | (0.508mm ±0.025mm) | (0.635mm ±0.025mm) | (0.762mm ±0.025mm) | (0.889mm ±0.025mm) | (1.016mm ±0.025mm) | (1.270mm ±0.127mm) | (1.778mm ±0.127mm) | (2.286mm ±0.127mm) | |

| (T) | inch | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" | 0.006" ±0.0025" |

| (mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | (0.153mm ±0.064mm) | |

| (T) for A - Dielectric | inch | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 | 0.007±0.002 |

| (mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | (0.177mm ±0.051mm) | |

| (B) | inch | 0.001" (0.0005" min.) | 0.001" (0.0005" min.) | 0.002" ±0.001" | 0.002" ±0.001" | 0.002" ±0.001" | 0.002" ±0.001" | 0.002" ±0.001" | 0.002" ±0.001" | 0.003" ±0.001" | 0.003" ±0.001" | 0.003" ±0.001" |

| (mm) | (0.025mm, 0.013mm min) | (0.025mm, 0.013mm min) | (0.051mm ±0.025mm) | (0.051mm ±0.025mm) | (0.051mm ±0.025mm) | (0.051mm ±0.025mm) | (0.051mm ±0.025mm) | (0.051mm ±0.025mm) | (0.076 ±0.025mm) | (0.076 ±0.025mm) | (0.076 ±0.025mm) | |

Download datasheet to view our capacitance selection in details

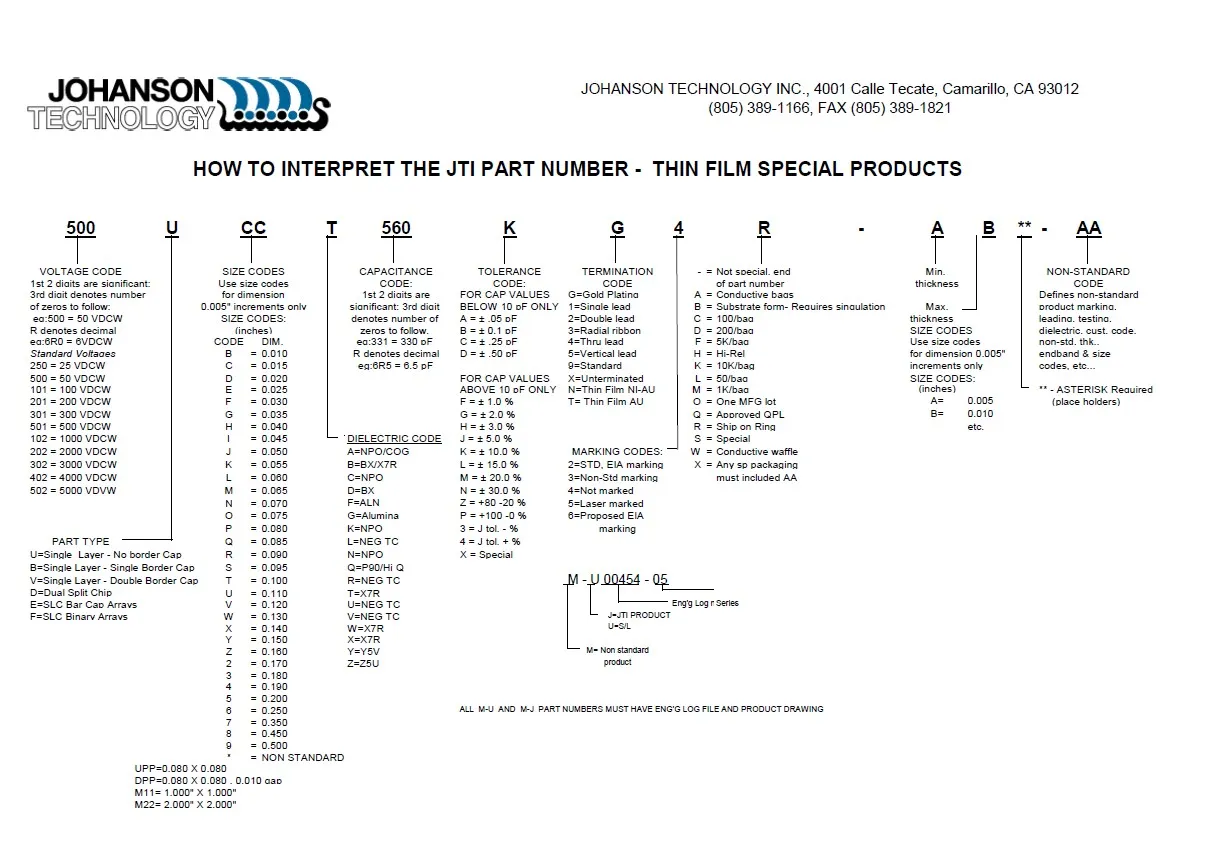

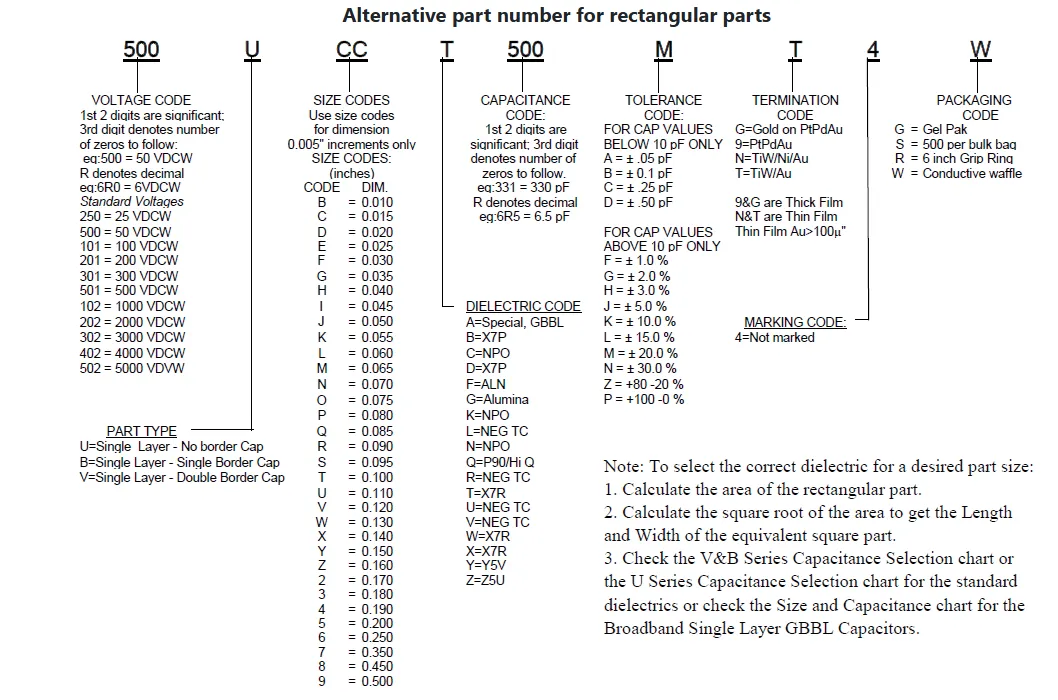

How to Order

Valid options are shown except for Capacitance

A typical PN is S0AA500G0R1A1ZZ001W. This part number breaks down as follows:

Capacitors Single Layer - No Bord, .010 x .010", NP0/C0G, 50V, 0.1pF±0.05pF, Special, Waffle Pack

New Johanson Global Part Number Breakdown

* Not all combinations create valid part numbers, ask our Apps Engineering Team for assistance creating a valid part number Request for assistanceClick below to see the new Global Part Number Reference Chart for this product