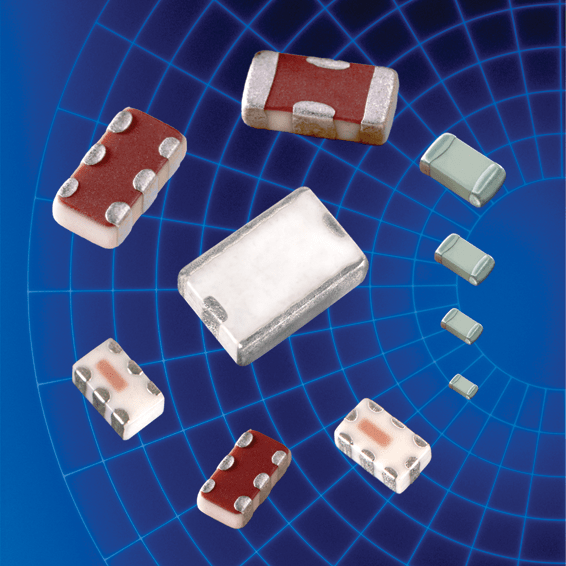

Integrated Passive Components ( RoHS Compliant)

Johanson Technology designs and manufactures a line of small, highly stable and integrated RF ceramic components manufactured with a proprietary LTCC (low temperature co-fired ceramic) process and materials. These components operate and thrive over several RF bands from 400MHz to 30GHz covering Cellular, DECT, WLAN, WiMax, all ISM, Bluetooth, 802.11 (a,b and g) and GPS applications.

Key Features:

- Custom Solutions

- LTCC (Low Temp Co-Fired Ceramics) Based Designs

- Low Insertion Loss

- Miniature Size / Ultra-Low Profiles

- Extremely Temperature Stable

- Surface Mount

- RoHS/REACH Compliant Standard, Use no Suffix

- AEC-Q200 Automotive Qualification (as required)

Supported Application Bands:

- All ISM bands (Industrial Scientific, and Medical)

- 315/433/783/868

- 915/950/2400MHz

- GSM/EDGE/GPRS

- PCS/WCDMA

- Wireless LAN

- Bluetooth

- HomeRF

- Zigbee operational bands

- GPS

- WiFi

- Zigbee

- UNII

- WiMAX 802.16

- MiMo

- UWB

Integrated Passive Components by Category

Chipset Specific Integrated Passive Components solutions

Ceramic Chip Antennas ( RoHS Compliant)

Applications:

- 88MHz-108MHz

- 400-500MHz

- 780MHz - 960MHz (ISM)

- 1.5 - 1.6 GHz (GPS)

- 1.9GHZ (DECT)

- 2.45 GHz (Bluetooth™, 802.11 b+g)

- 2.5 - 2.9 GHz

- 3.1 - 10.3 GHz (UWB)

- 5.4GHz WiFi

- 5.25 - 5.75 GHz (UNII, 802.11a)

RF Chip Antenna Training Module by Digi-Key

Download the PowerPoint Presentation:

LTCC Chip Antennas - How to Maximize Performance

In addition to the array of listed components we can support custom solutions for high volume applications with design flexibility and short development times.

Contact us today with your specific technical requirements.

Integrated Passive Components Information

Case Size Summary

Example Circuit Diagram

Part number Explanation

General format is: FFFFPPCCVBBBBT where:

FFFF is the 4 digit Frequency in Megahertz (unless otherwise specified)

PP is the 2 character Product code

| AT = Antenna | CP = Coupler |

| AM = Antenna Module Assembly | CF = Coupler Filter |

| AS = Antenna Switch Module | CH = Coupler Hybrid |

| AD = Dual-Band Antenna | DP = Diplexer |

| BL = Balun | FA = Filter Array |

| BD = Balun, Dual-Band | FB = Filter-Balun |

| M = Chipset Specific Impedance-Matched Balun or Balun-Filter | HP = High Pass Filter |

| BP = Band Pass Filter | LD = Low Pass Filter, Dual-Band |

| CD = Coupler, Dual Band | LP = Low Pass Filter |

| NF = Notch Filter (Band-Stop Filter) |

V is a 1 character Version/Revision code

BBBB is 3 or 4 digit Bandwidth, differential impedance (baluns only), or specific chipset denomination

T is the character tape code:

| Tape material | Code |

|---|---|

| Paper Tape standard (EIA 0603 and smaller) | T |

| Embossed Tape standard (EIA 0805 and larger) | E |

| Paper Tape rotated (non-std, EIA 0603 and smaller)* | A |

| Embossed Tape rotated (non-std, EIA 0805 and larger)* | R |

Examples:

- 0868AT43A0020E is an 868MHz antenna, case size 43, revision “A” with 20MHz of Bandwidth, embossed tape & reel

- 2450BM15A0002S is 2450MHz Impedance-matched Balun-BPF, case size 15 (EIA 0805), 100MHz BW, designed for to T.I. CC2530 chipset, bulk (loose) packaging

Soldering Profiles and Guidelines for SMT Ceramic Components

Typical Soldering Profile for Lead-free Process: RFCCs

Lead Free Solder, i.e. SAC 305, is recommended

| **Johanson Technology′s P/N's with Solderable Silver (Ag/Pt) Terminations requiring Vacuum Packaging | |||

|---|---|---|---|

| 0433BM15A0001 | 0868BM15C0001 | 0892DP15B1850 | 0892LP07A0136 |

| 0896BL14B050 | 0896BM15B0016 | 0900BL15A100 | 0900BL15C050 |

| 0915BM15A0001 | 1200BP44A575 | 1200LP41B0500 | 1200LP41C0500 |

| 1400BP41A0550 | 1810BP07B200 | 1900HP41B0500 | 1900HP41C0500 |

| 2025LP15A1225 | 1905BP18A0050 | 2450BM07A0004 | 2345FB39A0050 |

| 2450BL07A0100 | 2450BM15A0015 | 2450BM14E0007 | 2450BM15B0009 |

| 2450BP07A0100 | 2450BP08A0100 | 2450BP14D0100 | 2450BP14E0100 |

| 2450BP14F0100 | 2450BP15E0100 | 2450BP15F0100 | 2450BP15Q0100 |

| 2450BP39D100E | 2450BP15V0100 | 2450BP39D100C | 2450FB15A0100 |

| 2450BP39F100 | 2500BP15M400 | 2500FB16A0400 | 3350BP39A0500 |

| 2595FB16A0100 | 2600BP14M0200 | 3500FB39A0050 | 3600BP14M0600 |

| 3600BP15M600 | 0896FB15A0100 | 5400BP14A0950 | 5425BP15A1050 |

| 5525BP15B0750 | 2450BM08B0003 | 2450DP39K5400 | 2450DP39L5400 |

| 2450BL05A0100 | 2450FB15L0001 | 2450BM15B0003 | 0900PC15A0036 |

| 0845BL05A0100 | 0900FM15D0039 | 2025LP15B0145 | 2440AT62A0085 |

| 2440AT62B0085 | 2450BM14A0021 | 2450BP07C0100 | 2450BP08B0100 |

| 2450BP14G0100 | 2450BP14H0100 | 2450BP14J0100 | 2450FB14B0050 |

| 28R0BP44A1000 | 5235CR45A0180 | 5697CR45A0360 | 0900FM15D0039E |

| 5697CR45A0360E | 2440AT62A0085E | 2450FB15A050E | 5235CR45A0180E |

| 4700BP14A0600 | |||

Typical Soldering Profile for Tin / Lead Terminated Components:

Hand Soldering

The recommended temperature for hand soldering our integrated passives is 350C for 3-5sec max

Note:

The contents of this data sheet are subject to change without notice. Please confirm the specifications and delivery conditions when placing your order.

Lead Free Solder (SAC 305) is recommended