Microwave SLC Single Layer Capacitors

A Single Layer Capacitor is a rectangular or square piece of dielectric material with metallization across the top and bottom of the ceramic. These metallized layers form a bottom electrode contact, and top electrode contact (top contact normally formed using a wirebond).

Johanson Single Layer capacitors are offered in a wide range of dielectrics for very high frequency applications.

Available in sizes from 0.25 x 0.25mm (10 x 10mil) to 5 x 5mm (200 x 200mil), these single layer capacitors are used in military infrastructure and industrial markets.

In addition to their excellent performance, reliability and consistency in volume production has been the focus.

Key Features:

- Ceramic SLC Low Profile Devices Exhibit Very High-Q / Low Insertion Loss, SRFs to 50 GHz

- Thin film gold electrodes provide superior wire bonding & die attach performance

- Four SLC Device Types to Fit Many Applications:

- Standard (Die) SLCs

- Border SLCs

- Bar SLC Arrays

- Custom SLC Products

- RoHS - Available on all dielectrics

- Custom sizes are available - please consult factory

Applications:

- Microwave Integrated Components

- GaAs Integrated Circuits

- RF/Microswave Components

- DC Block, Bypass, Tuning

Microwave SLC Single Layer Capacitors Information

Dielectric

| Dielectric Code | Constant (K) | Temperature Coefficient * | Temperature Range | Dissipation Factor | Insulation Resistance | Test cond. | Available Tolerances |

|---|---|---|---|---|---|---|---|

| C | 23 | 0 ± 30ppm | -55°C to +125°C | ≤ 0.15%@1MHz | >1000 GΩ | 1 | B,C,D (A, <2pF) |

| K | 39 | 0 ± 30ppm | -55°C to +125°C | ≤ 0.15%@1MHz | >1000 GΩ | 1 | B,C,D (A, <2pF) |

| N | 76 | 0 ± 30ppm | -55°C to +125°C | ≤ 0.15%@1MHz | >1000 GΩ | 1 | B,C,D (A, <2pF) (F-K, >10pF) |

| V | 160 | -1500 + 500ppm / -946ppm | -55°C to +125°C | ≤ 0.25%@1MHz | >1000 GΩ | 1 | J,K (B-D) |

| R | 440 | -2200 + 500ppm / -1086ppm | -55°C to +125°C | ≤ 0.25%@1MHz | >1000 GΩ | 1 | J,K (B-D) |

| D | 725 | ± 10% | -55°C to +125°C | ≤ 2.50%@1KHz | >100 GΩ | 2 | K,M |

| B | 1410 | ± 10% | -55°C to +125°C | ≤ 2.50%@1KHz | >100 GΩ | 2 | K,M |

| W | 2300 | ± 15% | -55°C to +125°C | ≤ 2.50%@1KHz | >100 GΩ | 2 | K,M |

| X | 3150 | ± 15% | -55°C to +125°C | ≤ 2.50%@1KHz | >100 GΩ | 2 | K,M |

| T | 4100 | ± 15% | -55°C to +125°C | ≤ 2.50%@1KHz | >100 GΩ | 2 | K,M |

| Z | 8500 | +22% -56% | +10°C to +85°C | ≤ 4.00%@1KHz | >10 GΩ | 2 | M,Z |

| Y | 15000 | +22% -82% | -30°C to +85°C | ≤ 4.00%@1KHz | >10 GΩ | 2 | M,Z |

| Voltage Rating: |

50&100 WVDC

|

|---|---|

| Dielectric Strength: |

2.5 x WVDC min, 25°C, 50 mA max

|

| Test Conditions: |

1) 1.0±0.2 VRMS @ 1MHz, 25°C

2) for values ≤ 100pF: 1.0±0.2 VRMS @ 1MHz, 25°C; for ALL other Values: 1.0±0.2 VRMS @1KHz,25°C |

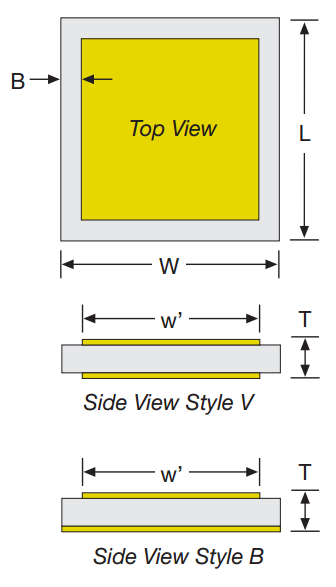

V & B-Series (Borders)

| SIZE | V10 | V12 | V15 | V20 | V25 | V30 | V40 | V50 |

|---|---|---|---|---|---|---|---|---|

| W&L ±.001" | .010 | .012 | .015 | .020 | .025 | .030 | .040 | .050 |

| (mm) | (0.25) | (0.30) | (0.38) | (0.51) | (0.64) | (0.76) | (1.02) | (1.27) |

| w' NOM. | .010 | .007 | .008 | .011 | .016 | .020 | .026 | .036 .044 |

| (mm) | (0.17) | (0.20) | (0.28) | (0.41) | (0.51) | (0.66) | (0.91) | (1.12) |

| B ±.001" | .001* | .001* | .002 | .002 | .002 | .002 | .002 | .003 |

| (mm) | (0.025)* | (0.025)* | (0.051) | (0.051) | (0.051) | (0.051) | (0.051) | (0.076) |

| T .002" | NOM. 0.004" ~ 0.008" | |||||||

| (mm) | (NOM. 0.10 ~ 0.20) | |||||||

|

*Min Border 0.0005"

Contact factory for other sizes, values or configurations |

||||||||

Recessed SLC electrode borders help prevent shorting from conductive epoxy squeeze-up and aid visual recognition equipment. The V-Series SLCs feature dual borders (top & bottom) while the B-Series SLCs feature a single border (top-only.)

| Cap. | V10 100V | V12 100V | V15 100V | V20 100V | V25 100V | V30 100V | V40 100V | V50 100V | |

|---|---|---|---|---|---|---|---|---|---|

| Value | Code | ||||||||

| 0.1 | 0R1 | C | C | C | |||||

| 0.2 | 0R2 | N | K | C | C | ||||

| 0.3 | 0R3 | N | N | K | C | C | |||

| 0.4 | 0R4 | V | N | N | K | C | |||

| 0.5 | 0R5 | V | N | N | K | C | C | ||

| 0.6 | 0R6 | V | V | N | K | K | C | ||

| 0.7 | 0R7 | V | V | V | N | K | C | ||

| 0.8 | 0R8 | R | V | V | N | K | C | ||

| 0.9 | 0R9 | R | V | V | N | K | C | C | |

| 1.0 | 1R0 | R | V | V | N | K | K | C | |

| 1.1 | 1R1 | R | R | V | N | N | K | C | |

| 1.2 | 1R2 | L | R | V | N | N | K | C | |

| 1.3 | 1R3 | L | R | R | N | N | K | C | |

| 1.4 | 1R4 | L | R | R | N | N | K | C | C |

| 1.5 | 1R5 | L | R | R | V | N | K | C | C |

| 1.6 | 1R6 | D | R | R | V | N | K | K | C |

| 1.7 | 1R7 | D | R | R | V | N | K | K | C |

| 1.8 | 1R8 | D | L | R | V | N | K | K | C |

| 1.9 | 1R9 | D | L | L | V | N | N | K | C |

| 2.0 | 2R1 | D | L | L | V | N | N | K | C |

| 2.1 | 2R1 | D | L | L | V | N | N | K | C |

| 2.2 | 2R2 | D | L | L | V | V | N | K | C |

| 2.4 | 2R4 | D | L | L | V | V | N | K | K |

| 2.7 | 2R7 | D | D | L | V | V | N | K | K |

| 3.0 | 2R0 | B | D | D | L | V | N | K | K |

| 3.3 | 3R3 | B | D | D | L | V | N | N | K |

| 3.6 | 3R6 | B | D | D | L | V | N | N | K |

| 3.9 | 3R9 | B | D | D | L | V | V | N | K |

| 4.3 | 4R3 | B | D | D | L | R | V | N | K |

| 4.7 | 4R7 | B | B | D | L | R | V | N | K |

| 5.1 | 5R1 | B | B | D | L | R | V | N | K |

| 5.6 | 5R6 | B | B | B | L | R | V | N | N |

| 6.2 | 6R2 | W | B | B | D | R | V | V | N |

| 6.8 | 6R8 | W | B | B | D | R | V | V | N |

| 7.5 | 7R5 | W | B | B | D | L | R | V | N |

| 8.2 | 8R2 | W | W | B | D | L | R | V | N |

| 9.1 | 9R1 | W | W | W | D | D | R | V | N |

| 10 | 100 | X | W | W | D | D | L | V | V |

| 12 | 120 | X | W | W | B | D | L | R | V |

| 15 | 150 | T | X | X | B | D | L | R | V |

| 18 | 180 | T | X | X | B | D | D | R | R |

| 20 | 200 | T | T | X | B | B | D | L | R |

| 22 | 220 | Z | T | T | B | B | D | L | R |

| 27 | 270 | Z | T | T | W | B | D | D | L |

| 33 | 330 | Y | Z | Z | W | B | B | D | L |

| 39 | 390 | Y | Z | Z | X | W | B | D | L |

| 47 | 470 | Y | Z | Z | X | W | B | D | D |

| 50 | 500 | Y | Y | Z | X | W | B | D | D |

| 51 | 510 | Y | Y | Z | T | X | B | D | D |

| 56 | 560 | Y | Y | Y | T | X | B | B | D |

| 68 | 680 | Y | Y | T | X | W | B | D | |

| 82 | 820 | Y | Y | Z | T | W | B | D | |

| 100 | 101 | Y | Z | T | X | W | B | ||

| 120 | 121 | Z | T | X | W | B | |||

| 150 | 151 | Y | Z | T | X | W | |||

| 180 | 181 | Y | Z | T | T | W | |||

| 200 | 201 | Y | Z | T | T | X | |||

| 220 | 221 | Y | Z | T | X | ||||

| 270 | 271 | Y | Z | T | X | ||||

| 330 | 331 | Y | Y | Z | T | ||||

| 390 | 391 | Y | Z | T | |||||

| 470 | 471 | Y | Z | T | |||||

| 560 | 561 | Y | Y | Z | |||||

| 680 | 681 | Y | Z | ||||||

| 820 | 821 | Y | |||||||

| 1000 | 102 | Y | |||||||

| 1200 | 122 | Y | |||||||

Color breaks used to highlight changes in dielectric material, letters indicate the specific material.

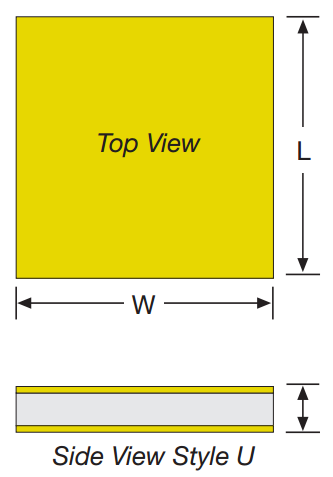

U Series SLC Capacitance Selection (No border)

| CAPACITANCE | U10 | U12 | U15 | U20 | U25 | U30 | U35 | U50 | U70 | U90 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Value | Code | 50V | 50V | 50V | 100V | 50V | 100V | 50V | 100V | 50V | 100V | 50V | 100V | 100V | 100V | 100V |

| 0.1 | 0R1 | C | ||||||||||||||

| 0.2 | 0R2 | K | C | C | ||||||||||||

| 0.3 | 0R3 | N | K | C | K | C | ||||||||||

| 0.4 | 0R4 | N | N | K | K | C | C | C | ||||||||

| 0.5 | 0R5 | U | N | K | N | C | K | C | ||||||||

| 0.6 | 0R6 | V | N | K | N | C | K | C | C | C | ||||||

| 0.7 | 0R7 | V | N | N | N | K | K | C | K | C | C | |||||

| 0.8 | 0R8 | V | U | N | N | K | N | C | K | C | C | |||||

| 0.9 | 0R9 | R | V | N | U | K | N | C | K | C | C | C | ||||

| 1.0 | 1R0 | R | V | N | U | K | N | K | K | C | K | C | C | |||

| 1.1 | 1R1 | R | V | N | V | K | N | K | K | C | K | C | C | C | ||

| 1.2 | 1R2 | R | V | N | V | N | N | K | N | C | K | C | C | C | ||

| 1.3 | 1R3 | R | V | N | V | N | N | K | N | C | K | C | K | C | ||

| 1.4 | 1R4 | L | V | U | V | N | N | K | N | K | K | C | K | C | ||

| 1.5 | 1R5 | L | V | U | V | N | N | K | N | K | K | C | K | C | ||

| 1.6 | 1R6 | L | R | U | V | N | U | K | N | K | N | C | K | C | ||

| 1.7 | 1R7 | L | R | U | V | N | U | K | N | K | N | C | K | C | ||

| 1.8 | 1R8 | L | R | U | R | N | U | N | N | K | N | K | K | C | ||

| 1.9 | 1R9 | L | R | V | R | N | U | N | N | K | N | K | K | C | ||

| 2.0 | 2R1 | D | R | V | R | N | U | N | N | K | N | K | K | K | ||

| 2.1 | 2R1 | D | L | V | R | N | V | N | N | K | N | K | K | K | C | |

| 2.2 | 2R2 | D | L | V | R | U | V | N | U | K | N | K | N | K | C | |

| 2.4 | 2R4 | D | L | V | R | U | V | N | U | K | N | K | N | K | C | |

| 2.7 | 2R7 | D | L | R | L | U | V | N | U | N | N | K | N | K | C | C |

| 3.0 | 2R0 | D | L | R | L | U | V | N | U | N | N | K | N | K | C | C |

| 3.3 | 3R3 | D | L | R | L | V | R | N | V | N | U | K | N | K | C | C |

| 3.6 | 3R6 | D | D | R | L | V | R | U | V | N | U | K | N | K | C | C |

| 3.9 | 3R9 | B | D | R | L | V | R | U | V | N | U | N | N | N | C | C |

| 4.3 | 4R3 | B | D | R | D | V | R | U | V | N | V | N | N | N | C | C |

| 4.7 | 4R7 | B | D | L | D | R | R | U | R | N | V | N | N | N | K | C |

| 5.1 | 5R1 | B | D | L | D | R | R | V | R | U | V | N | U | N | K | C |

| 5.6 | 5R6 | B | D | L | D | R | L | V | R | U | V | N | U | N | K | K |

| 6.2 | 6R2 | B | D | D | D | R | L | V | R | U | V | N | U | N | K | K |

| 6.8 | 6R8 | B | B | D | D | R | L | R | R | V | R | N | V | N | K | K |

| 7.5 | 7R5 | W | B | D | D | R | D | R | L | V | R | U | V | N | K | K |

| 8.2 | 8R2 | W | B | D | B | L | D | R | L | V | R | U | V | N | N | K |

| 9.1 | 9R1 | W | B | D | B | L | D | R | L | V | R | U | R | N | N | N |

| 10 | 100 | X | B | D | B | L | D | R | L | R | L | V | R | V | N | N |

| 12 | 120 | X | W | B | B | D | D | L | D | R | L | V | R | V | N | N |

| 15 | 150 | T | W | B | W | D | B | L | D | R | L | R | L | V | N | N |

| 18 | 180 | T | W | B | W | D | B | D | D | L | D | R | L | V | V | N |

| 20 | 200 | T | X | W | W | D | B | D | D | L | D | R | D | R | V | N |

| 22 | 220 | T | X | W | X | B | B | D | B | L | D | R | D | R | V | N |

| 27 | 270 | Z | T | W | X | B | W | D | B | D | D | L | D | R | V | U |

| 33 | 330 | Z | T | X | T | B | W | B | D | D | B | L | D | L | R | U |

| 39 | 390 | Z | T | X | T | W | X | B | W | D | B | D | B | L | R | V |

| 47 | 470 | Y | Z | T | T | W | X | B | W | D | B | D | B | D | R | V |

| 50 | 500 | Y | Z | T | Z | W | X | B | W | B | B | D | B | D | R | V |

| 51 | 510 | Y | Z | T | Z | W | X | B | W | B | B | D | B | D | R | R |

| 56 | 560 | Y | Z | T | Z | W | T | B | X | B | W | D | B | D | R | R |

| 68 | 680 | Z | Z | Z | X | T | W | X | B | W | B | W | D | L | R | |

| 82 | 820 | Y | Z | Y | T | Z | W | T | B | X | B | X | B | D | R | |

| 100 | 101 | Y | Z | Y | T | Z | X | T | W | X | B | X | B | D | L | |

| 120 | 121 | Y | Y | T | Z | T | T | W | T | W | X | B | D | D | ||

| 150 | 151 | Y | Z | Y | T | Z | X | T | W | X | B | B | D | |||

| 180 | 181 | Y | Z | Y | T | Z | T | T | W | T | W | B | D | |||

| 200 | 201 | Z | Y | Z | Z | T | Z | X | T | W | B | B | ||||

| 220 | 221 | Y | Y | Z | Z | T | Z | X | T | W | B | B | ||||

| 270 | 271 | Y | Z | Y | T | Z | T | Z | X | W | B | |||||

| 330 | 331 | Y | Y | Y | Z | Z | T | Z | X | W | W | |||||

| 390 | 391 | Y | Z | Y | T | Z | T | X | W | |||||||

| 470 | 471 | Y | Z | Y | Z | Y | T | X | W | |||||||

| 560 | 561 | Y | Y | Z | Y | T | T | X | ||||||||

| 680 | 681 | Y | Z | Y | Z | T | X | |||||||||

| 820 | 821 | Y | Z | T | X | |||||||||||

| 1000 | 102 | Y | Z | T | T | |||||||||||

| 1200 | 122 | Y | Z | T | ||||||||||||

| 1500 | 152 | Y | Y | Z | ||||||||||||

| 1800 | 182 | Y | Z | |||||||||||||

| 2000 | 202 | Y | Z | |||||||||||||

| 2500 | 252 | Y | Y | |||||||||||||

| 4000 | 402 | Y | ||||||||||||||

Color breaks used to highlight changes in dielectric material, letters indicate the specific material.

V-Series & B-Series Mechanical Characteristics

| Size | V10 | V12 | V15 | V20 | V25 | V30 | V40 | V50 |

|---|---|---|---|---|---|---|---|---|

| W&L ±.001" (mm) | .010 (0.25) | .012 (0.30) | .015 (0.38) | .020 (0.51) | .025 (0.64) | .030 (0.76) | .040 (1.02) | .050 (1.27) |

| W' NOM. (mm) | .008 (0.20) | .010 (0.25) | .011 (0.28) | .016 (0.41) | .020 (0.51) | .026 (0.66) | .036 (0.91) | .044 (1.12) |

| B ±.001" (mm) | .001* (0.025) | .001* (0.025) | .002 (0.51) | .002 (0.51) | .002 (0.51) | .002 (0.51) | .002 (0.51) | .003 (0.76) |

| T ±.001" (mm) | .006 (0.15) | .006 (0.15) | .006 (0.15) | .006 (0.15) | .006 (0.15) | .006 (0.15) | .006 (0.15) | .006 (0.15) |

|

*Min Border 0.0005" Contact factory for other sizes, values or configurations |

||||||||

| Size | U10 | U12 | U15 | U20 | U25 | U30 | U35 | U50 | U70 | U90 |

|---|---|---|---|---|---|---|---|---|---|---|

| W +.001" -.003" (mm) |

.010 (0.25) |

.012 (0.30) |

.015 (0.38) |

.020 (0.51) |

.025 (0.64) |

.030 (0.76) |

.035 (0.89) |

.050 (1.27) |

.070 (1.78) |

.090 (2.29) |

| L MAX. (mm) |

.012 (0.30) |

.015 (0.38) |

.020 (0.51) |

.025 (0.64) |

.030 (0.76) |

.035 (0.89) |

.040 (1.02) |

.060 (1.52) |

.080 (2.03) |

.100 (2.54) |

| T ±.002" (mm) |

NOM. 0.004" ~ 0.008" (NOM. 0.10 ~ 0.20) |

|||||||||

| Contact factory for other sizes, values or configurations | ||||||||||

SLC Temperature Characteristics

Metallization Characteristics

| Metallization Type | TiW/Au (Titanium-Tungsten/Gold) | TiW/Ni/Au (Titanium-Tungsten/Nickel/Gold) |

|---|---|---|

| Termination Code | T | N |

| Attachment Compatibility | Wire / Ribbon Bonding Silver or Gold Conductive Epoxy Au/Ge or Au/Si Eutectic Preform Excellent High Temperature Resistance (400°C) Unsuitable for Pb/Sn or Au/Sn Soldering |

Pb/Sn or Au/Sn Soldering Au/Sn Eutectic Preform Moderate High Temp. Resistance (325°C) Long term high temperature may cause Ni diffusion and wire bond problems on Au/Ge |

SLC thick-film terminations ( legacy codes "G" and "9") are still supported. Contact the factory for compatibility information.

Environmental Characteristics

| Bond Strength | Exceeds MIL-S-883, Meth. 2011 | Vibration: | MIL-S-202, Meth. 204-G, (30g, 10-2000 Hz) |

|---|---|---|---|

| Shear Strength | Exceeds MIL-S-883, Meth. 2019 | Burn-In/Life Test: | MIL-S-202, Meth. 108, A/F |

| Solder Heat Resistance | MIL-S-202, Meth. 210-C, (260±5°C, 5 sec.) | Low Voltage Humidity: | Mil-C-49464, Para. 3.17 |

| Solderability: | MIL-S-202, Meth. 208, (245±5°C, 5 sec.) | Barometric Pressure: | MIL-S-202, Meth. 105, B |

| Shock: | MIL-S-202, Meth. 213-I, (100g, 6 msec.) | Immersion/Salt Spray: | MIL-S-202, Meth. 104, B |

| Thermal Shock: | MIL-S-202, Meth. 107, A, (-55 to +125°C) | Moisture Resistance: | MIL-S-202, Meth. 106 |

Alternative part number for rectangular parts

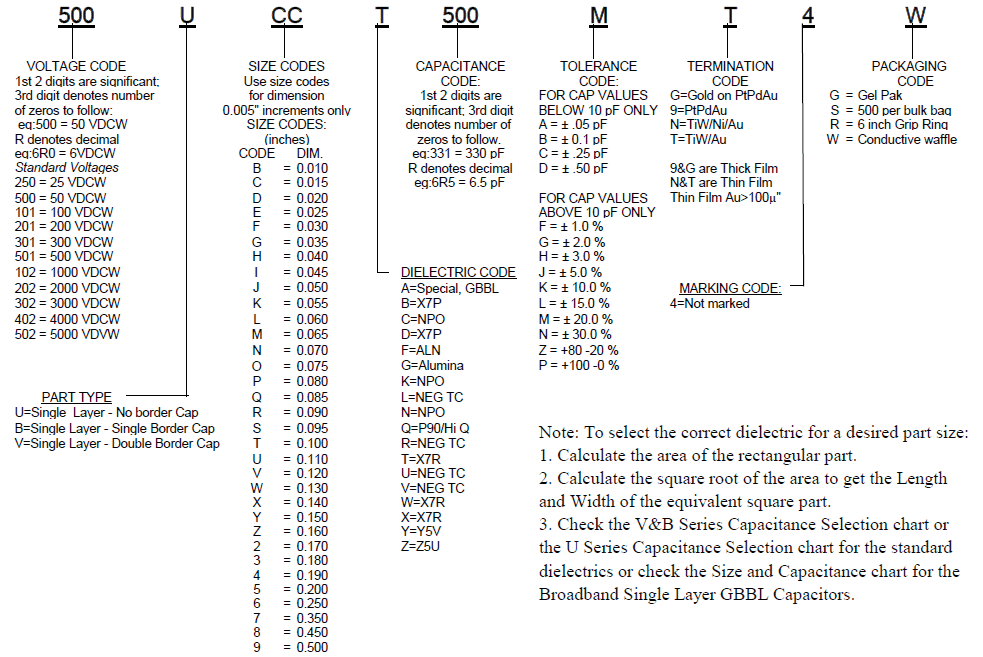

How to Order

Valid options are shown except for Capacitance

A typical PN is S0AL500B100K1S1001W. This part number breaks down as follows:

Capacitors Single Layer - No Bord, .015 x .015", BX, 50V, 10pF±10%, TiW/Ni/Au, Waffle Pack

New Johanson Global Part Number Breakdown

* Not all combinations create valid part numbers, ask our Apps Engineering Team for assistance creating a valid part number Request for assistanceClick below to see the new Global Part Number Reference Chart for this product

Legacy How to Order Information