Tape & Reel Packaging

Johanson Technology has produced a number of applications notes on various topics of discussion to provide a better understanding of the operation of RF passive products.

Chip Capacitor Tape & Reel Packaging

Johanson capacitors are available taped per EIA standard 481. Tape options include 5", 7" and 13" diameter reels. Johanson uses high quality, dust free, punched 8mm paper tape and plastic embossed 8mm tape for thicker MLCs. Quantity per reel ranges are listed in the tables below and are dependent on chip thickness.

| TYPE/SIZE | REEL QUANTITY | TAPE TYPE | TAPE CODE | REEL QUANTITY | TAPE TYPE | TAPE CODE | REEL QUANTITY | TAPE TYPE | TAPE CODE |

|---|---|---|---|---|---|---|---|---|---|

| R03/01005 | 20,000 | Paper | Y | 30,000 | Paper | T | N/A | N/A | N/A |

| R05/0201 | 500 | Paper | Y | 15,000 | Paper | T | N/A | N/A | N/A |

| R07/0402 | 500 | Paper | Y | 10,000 | Paper | T | N/A | N/A | N/A |

| R14/0603 | 500 | Paper | Y | 4,000 | Paper | T | 10,000 | Paper | R |

| R15/0805 | 500 | Embossed | Z | 4,000 | Embossed | E | 10,000 | Embossed | U |

| R15/0805 Vertical | 500 | Embossed | Q | 3,000 | Embossed | P | N/A | N/A | N/A |

| S42/1111 | 500 | Embossed | Z | 2,000 | Embossed | E | 10,000 | Embossed | U |

| S42/1111 Vertical | 500 | Embossed | Q | 1,000 | Embossed | P | N/A | N/A | N/A |

| S48/2525 | N/A | 250 | Embossed | E | 1,000 | Embossed | U | ||

| S58/3838 | N/A | 250 | Embossed | E | 1,000 | Embossed | U | ||

| LASERtrim® (ALL) | 500 | Paper | Y | 4.5-5.0K | Paper | T | 15,000 | Paper | R |

| SUBSTRATES - DEPENDS ON SIZE, TYPICAL IS 10/BOX CAP ARRAYS-100/TRAY SINGLE LAYER CAPACITORS - UP TO 50 MIL, 400/WAFFLE PACK; >50 MIL, 100/WAFFLE PACK SLC'S CAN ALSO BE MOUNTED ON GRIP RINGS, RING FRAMES, AND SURFTAPE CUSTOM PACKAGING AND QUANTITIES ARE AVAILABLE, CONTACT THE FACTORY FOR OPTIONS PLEASE VISIT OUR WEBSITE FOR RF CERAMIC COMPONENTS PACKAGING INFORMATION. |

|||||||||

Inductor Tape & Reel Packaging

| Type | A | A' | B | C | D | T |

|---|---|---|---|---|---|---|

| L-05B | 2.0±0.05 | 4.0±0.1 | 0.38±0.02 | 0.68±0.02 | 2.0±0.05 | Max.0.44 |

| L-07C | 2.0±0.1 | 4.0±0.1 | 0.6±0.1 | 1.1±0.1 | 2.0±0.1 | Max.1.0 |

| L-14C | 4.0±0.1 | 4.0±0.1 | 1.0±0.1 | 1.8±0.1 | 2.0±0.1 | Max.1.3 |

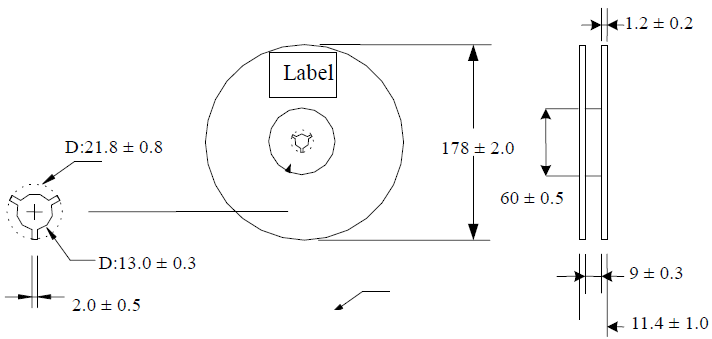

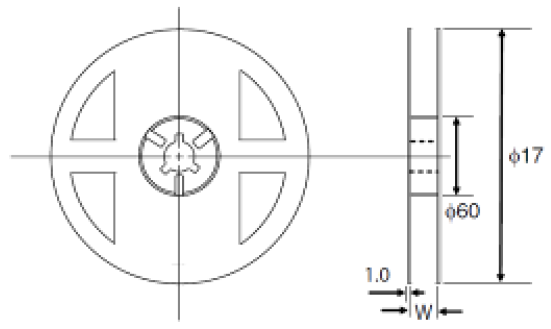

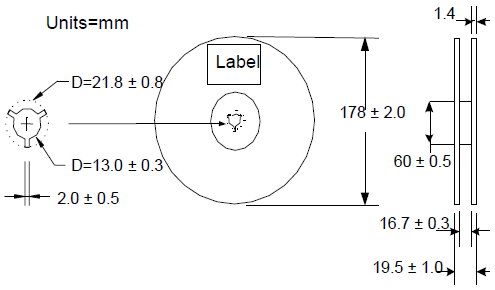

Reel Dimensions (Unit: mm)

Quantity

| Type | L-05B | L-07C | L-14C |

|---|---|---|---|

| Quantity/reel | 15,000 pcs | 10,000 pcs | 4,000 pcs |

| Tape material | Paper | Paper | Paper |

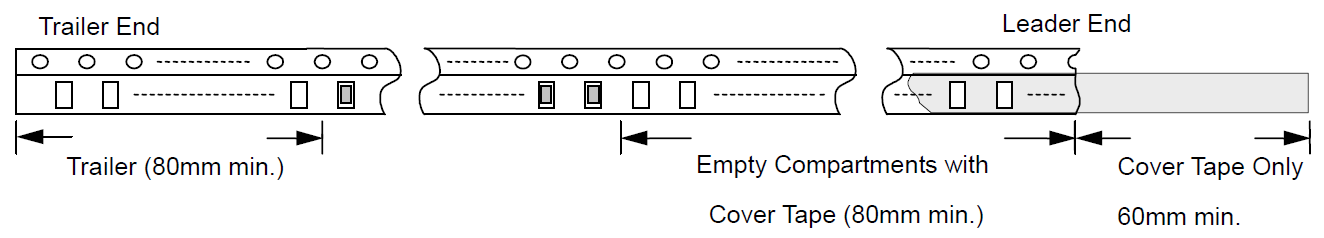

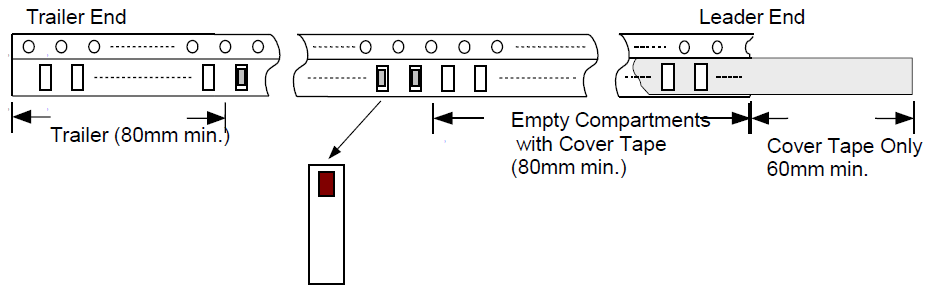

Leader / Trailer Tape (Unit: mm)

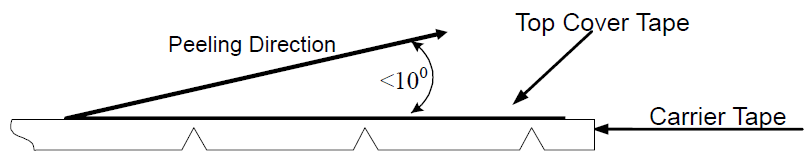

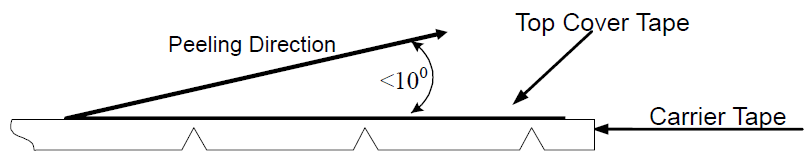

Peel-off Force

Peel-off force should be in the range of 0.1 – 0.6 N at a peel-off speed of 300±10 mm/min.

Notes

The contents of this data sheet are subject to change without notice. Please confirm the specifications and delivery conditions when placing your order.

Wirewound Inductor Packaging Information

| TYPE/SIZE | REEL QUANTITY | TAPE TYPE | TAPE CODE |

|---|---|---|---|

| L-07/0402 | 10,000 | Paper | T |

| L-14/0603 | 3,000 | Embossed | E |

| L-15/0805 | 2,000 | Embossed | E |

| Type | A | B | F | K | T | W |

|---|---|---|---|---|---|---|

| L-07 | 0.70 | 1.20 | 2.00 | - | 0.70 | 8.00 |

| L-14 | 1.25 | 1.80 | 4.00 | 1.10 | 0.20 | 8.00 |

| L-15 | 1.42 | 2.26 | 4.00 | 1.30 | 0.20 | 8.00 |

RF Antenna Tape & Reel Packaging

Reel Specifications

| JTI Size Code | Size Metric | Reel Qty |

|---|---|---|

| AT07 | 1005 | 10,000 |

| AT14 | 1608 | 4,000 |

| AT18 | 3216 | 3,000 |

| AT42 | 5020 | 2,000 |

| AT43 | 7020 | 1,000 |

| AT44 | 7635 | 1,000 |

| AT45 | 9520 | 1,000 |

| AT46 | 8516 | 1,000 |

| AT47 | R130 | 1,000 |

Tape Specifications

| Size Code | Size Metric | A | A' | B | C | D | E | F | t | T |

|---|---|---|---|---|---|---|---|---|---|---|

| AT07 | 1005 | 2.0 ± 0.05 | 4.0 ± 0.1 | 0.62 ± 0.03 | 1.12 ± 0.03 | 2.0 ± 0.05 | 3.5 ± 0.05 | 8.0 ± 0.1 | 0.20 ± 0.05 | 1.0 Max. |

| AT14 | 1608 | 4.0 ± 0.1 | 4.0 ± 0.1 | 0.95 ± 0.1 | 1.80 ± 0.1 | 2.0 ± 0.1 | 3.5 ± 0.05 | 8.0 ± 0.1 | 0.20 ± 0.05 | 1.0 Max. |

| AT18 | 3216 | 4.0 ± 0.1 | 4.0 ± 0.1 | 1.90 ± 0.1 | 3.50 ± 0.1 | 2.0 ± 0.1 | 3.5 ± 0.05 | 8.0 ± 0.1 | 0.20 ± 0.05 | 1.40 Max. |

| AT42 | 5020 | 4.0 ± 0.1 | 4.0 ± 0.1 | 2.40 ± 0.1 | 5.50 ± 0.1 | 2.0 ± 0.1 | 5.5 ± 0.1 | 12.2 ± 0.2 | 0.20 ± 0.05 | 1.40 Max. |

| AT43 | 7020 | 4.0 ± 0.1 | 4.0 ± 0.1 | 2.40 ± 0.1 | 7.30 ± 0.1 | 2.0 ± 0.1 | 5.5 ± 0.1 | 12.2 ± 0.2 | 0.22 ± 0.05 | 1.55 Max. |

| AT44 | 7635 | 8.0 ± 0.1 | 4.0 ± 0.1 | 3.75 ± 0.1 | 7.85 ± 0.1 | 2.0 ± 0.1 | 7.5 ± 0.1 | 16 ± 0.2 | 0.30 ± 0.05 | 1.40 Max. |

| AT45 | 9520 | 4.0 ± 0.1 | 4.0 ± 0.1 | 2.30 ± 0.1 | 9.70 ± 0.1 | 2.0 ± 0.1 | 7.5 ± 0.1 | 16 ± 0.2 | 0.22 ± 0.05 | 1.45 Max. |

| AT46 | 8516 | 4.0 ± 0.1 | 4.0 ± 0.1 | 1.85 ± 0.1 | 8.70 ± 0.1 | 2.0 ± 0.1 | 7.5 ± 0.1 | 16 ± 0.2 | 0.25 ± 0.05 | 1.40 Max. |

| AT47 | R130 | 8.0 ± 0.1 | 4.0 ± 0.1 | 3.35 ± 0.1 | 10.35 ± 0.1 | 2.0 ± 0.1 | 7.5 ± 0.1 | 16 ± 0.2 | 0.25 ± 0.05 | 1.40 Max. |

Tape Peel Strength

Peel-off force should be in the range of 0.1 – 0.6 N at a peel--off speed of 300 ±10 mm/min.

Storage Conditions:

- Temperature:15 to 35 °C,Relative Humidity (RH):45 to 75%.

- Non-corrosive environment

- Products should be used within six months of receipt.

IPC Tape & Reel packaging

1. Taping Specifications

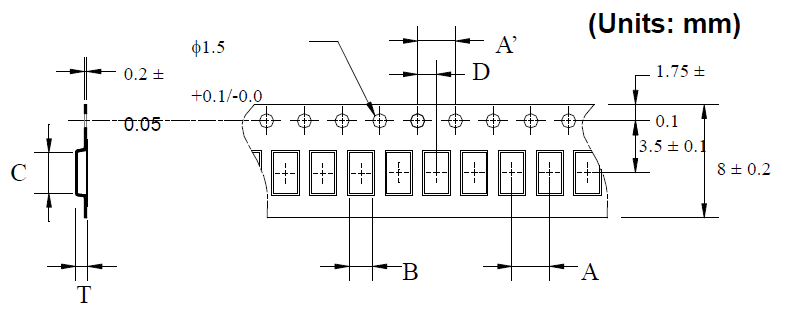

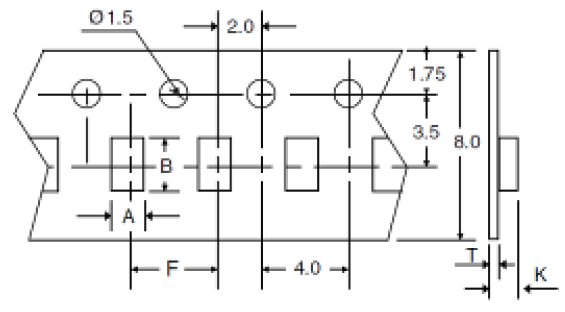

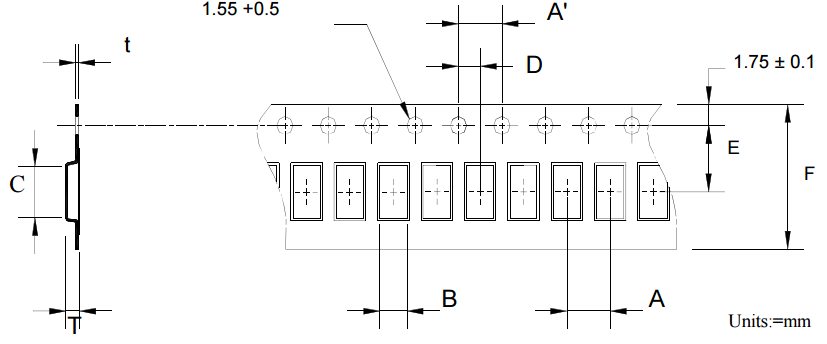

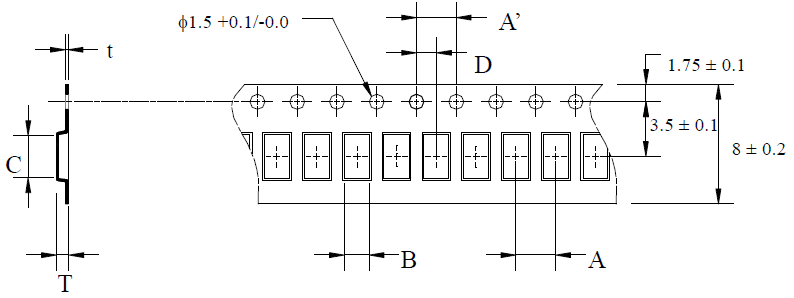

a. Tape Dimensions (Units: mm)

| JTI Size Code | Size EIA | Size Metric | A | A' | B | C | D | t | T |

|---|---|---|---|---|---|---|---|---|---|

| 07 | 0402 | 1005 | 2.0±0.1 | 4.0±0.1 | 0.6±0.1 | 1.1±0.1 | 2.0±0.1 | 0.20±0.05 | Max.1 |

| 14 | 0603 | 1608 | 4.0±0.1 | 4.0±0.1 | 1.1±0.1 | 1.92±0.1 | 2.0±0.1 | 0.20±0.05 | Max.0.85 |

| 15 | 0805 | 2012 | 4.0±0.1 | 4.0±0.1 | 1.6±0.1 | 2.4±0.1 | 2.0±0.1 | 0.20±0.05 | Max.1.3 |

| 39 | 1008 | 2520 | 4.0±0.1 | 4.0±0.1 | 2.35±0.1 | 2.8±0.1 | 2.0±0.1 | 0.22±0.05 | Max.1.45 |

| 18 | 1206 | 3216 | 4.0±0.1 | 4.0±0.1 | 1.9±0.1 | 3.5±0.1 | 2.0±0.1 | 0.20±0.05 | Max.1.4 |

| 41 | 1210 | 3225 | 4.0±0.1 | 4.0±0.1 | 2.68±0.1 | 3.46±0.1 | 2.0±0.1 | 0.23±0.05 | Max.1.84 |

| 43A | 1812 | 4532 | 4.0±0.1 | 4.0±0.1 | 2.35±0.1 | 7.4±0.1 | 2.0±0.1 | 0.25±0.05 | Max.4.5 |

| 43/44 | 1812 | 4532 | 8.0±0.1 | 4.0±0.1 | 4.18±0.1 | 4.95±0.1 | 2.0±0.1 | 0.24±0.05 | Max.1.95 |

Dimensions are typical – see EIA 481 for detail information.

b. Quantities per Reel According to component size

| JTI Size Code | 07 | 14 | 15 | 39 | 18 | 41 | 43A | 43/44 |

|---|---|---|---|---|---|---|---|---|

| Size EIA | 0402 | 0603 | 0805 | 1008 | 1206 | 1210 | 1812 | 1812 |

| Size Metric | 1005 | 1608 | 2012 | 2520 | 3216 | 3225 | 4532 | 4532 |

| Quantity/reel | 10,000pcs | 4,000pcs | 4,000pcs | 3,000pcs | 3,000pcs | 2,000pcs | 500pcs | 2,000pcs |

| Tape material | paper | paper | Plastic (Embossed) | Plastic (Embossed) | Plastic (Embossed) | Plastic (Embossed) | Plastic (Embossed) | Plastic (Embossed) |

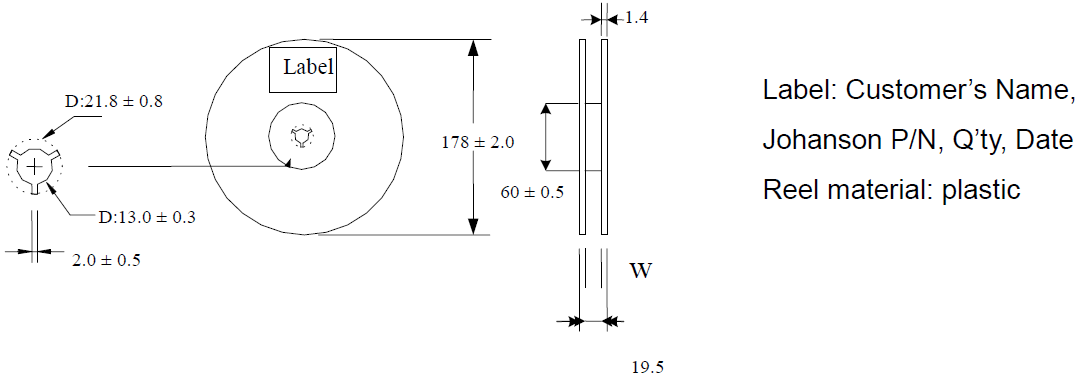

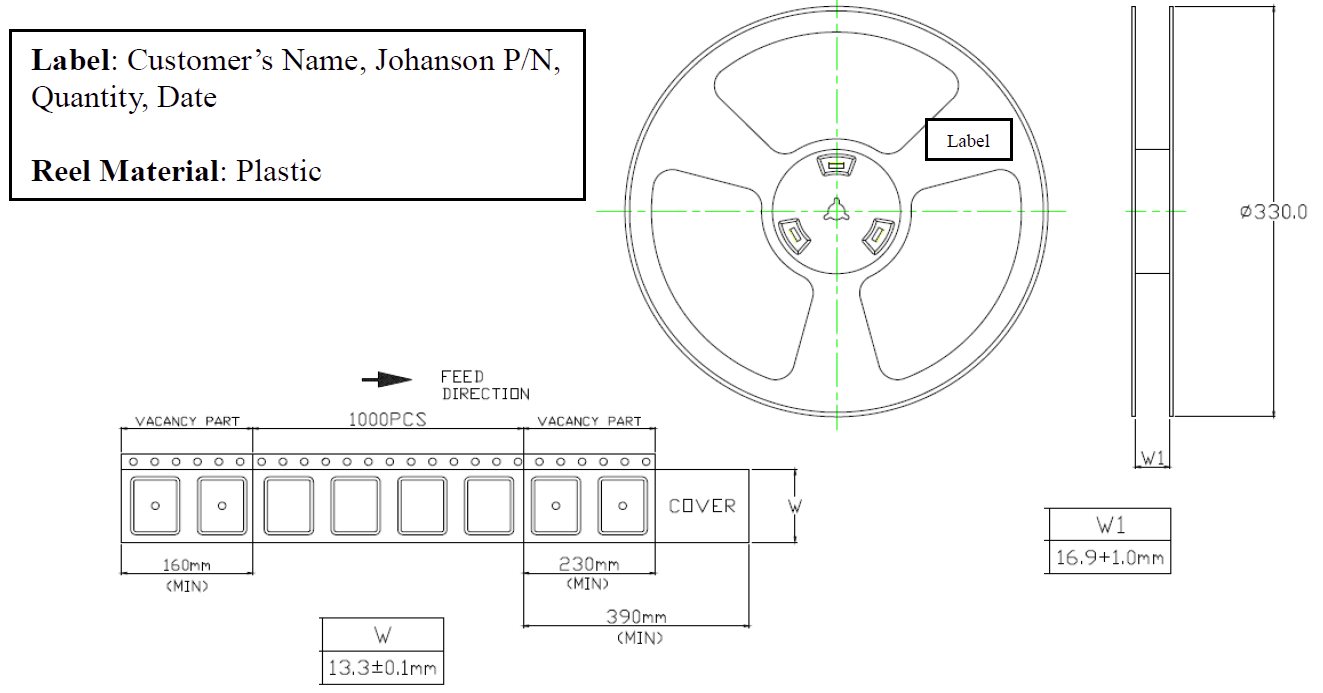

2. Reel Dimensions (Units: mm)

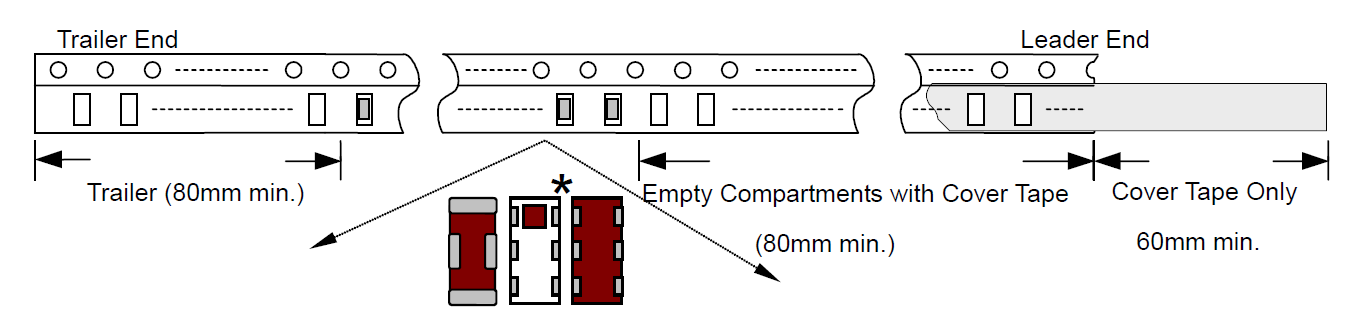

3. Taping Specifications

a. For case sizes EIA 0603 and smaller, paper tape is used. For case sizes EIA 0805 and larger, embossed (plastic) tape is used.

*Non-standard top red mark rotated 180 deg w.r.t. tape may be available on certain components, please consult the factory for availability and MOQs that apply.

b. P/N Codes (last digit) for T&R:

| Tape material | Code |

| Paper Tape standard | T |

| Embossed Tape standard | E |

| Paper Tape rotated (non-std) | A |

| Embossed Tape rotated (non-std) | R |

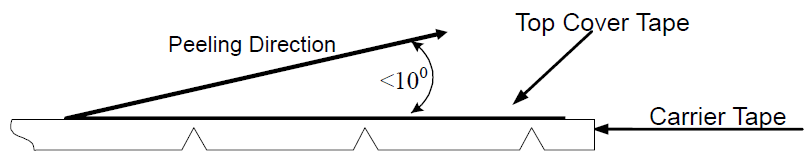

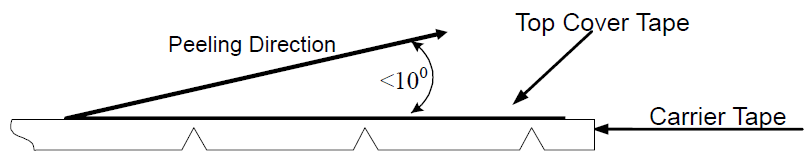

4. Peel-off Force

Peel-off force should be in the range of 0.1 – 0.6 N at a peel--off speed of 300 ±10 mm/min.

5. Storage Conditions

- Temperature: 15 - 35° C and relative humidity (RH): 45 - 75%.

- Non-corrosive environment

- It is recommended that product be used within 18 months of receipt

The following p/n's require vacuum sealed packaging when stored (due to Ag (silver) termination):

| 0433BM15A0001 | 0868BM15C0001 | 0892DP15B1850 | 0892LP07A0136 |

| 0896BL14B050 | 0896BM15B0016 | 0900BL15A100 | 0900BL15C050 |

| 0915BM15A0001 | 1200BP44A575 | 1200LP41B0500 | 1200LP41C0500 |

| 1400BP41A0550 | 1810BP07B200 | 1900HP41B0500 | 1900HP41C0500 |

| 2025LP15A1225 | 1905BP18A0050 | 2450BM07A0004 | 2345FB39A0050 |

| 2450BL07A0100 | 2450BM15A0015 | 2450BM14E0007 | 2450BM15B0009 |

| 2450BP07A0100 | 2450BP08A0100 | 2450BP14D0100 | 2450BP14E0100 |

| 2450BP14F0100 | 2450BP15E0100 | 2450BP15F0100 | 2450BP15Q0100 |

| 2450BP39D100E | 2450BP15V0100 | 2450BP39D100C | 2450FB15A0100 |

| 2450BP39F100 | 2500BP15M400 | 2500FB16A0400 | 3350BP39A0500 |

| 2595FB16A0100 | 2600BP14M0200 | 3500FB39A0050 | 3600BP14M0600 |

| 3600BP15M600 | 0896FB15A0100 | 5400BP14A0950 | 5425BP15A1050 |

| 5525BP15B0750 | 2450BM08B0003 | 2450DP39K5400 | 2450DP39L5400 |

| 2450BL05A0100 | 2450FB15L0001 | 2450BM15B0003 | 0900PC15A0036 |

| 0845BL05A0100 | 0900FM15D0039 | 2025LP15B0145 | 2440AT62A0085 |

| 2440AT62B0085 | 2450BM14A0021 | 2450BP07C0100 | 2450BP08B0100 |

| 2450BP14G0100 | 2450BP14H0100 | 2450BP14J0100 | 2450FB14B0050 |

| 28R0BP44A1000 | 5235CR45A0180 | 5697CR45A0360 | 0900FM15D0039E |

| 5697CR45A0360E | 2440AT62A0085E | 2450FB15A050E | 5235CR45A0180E |

| 4700BP14A0600 | |||

Ceramic Resonator Filter Tape & Reel Packaging

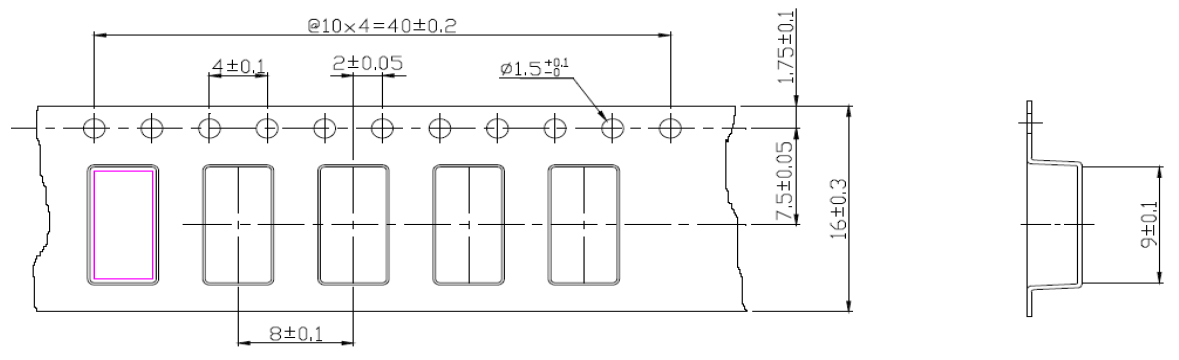

Tape Dimensions & Quantity (Units in mm)

| Applicable Part Numbers |

|---|

| 5697CR45A0031E |

| 5697CR45A0360E |

| 5697BP45A0360E |

| Applicable Part Numbers |

|---|

| 5235CR45A0031E |

| 5235CR45A0180E |

| 5235BP45A0180E |

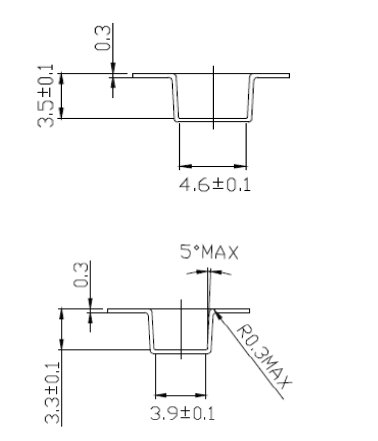

Reel Dimensions (Units in mm)

Peel-off Force

Peel-off force should be in the range of 0.1 - 0.6 N at a peel-off speed of 300±10 mm/min.

Recommended Storage Conditions for unused product on T&R

- Temperature: 15 - 35° C and relative humidity (RH): 45 - 75%

- Non-corrosive environment

- It is recommended that product be used within 18 months of reciept.

Due to silver terminiations, these components require vacuum sealed packaging when stored